LyondellBasell Australia Collaborates to Create Food Packaging Prototype with Recycled Content

LyondellBasell has unveiled a new food packaging prototype in Australia, made from recycled content and designed to support a closed-loop circular economy in plastics.

LyondellBasell joined a group of companies to co-develop a prototype KitKat wrapper made with 30% recycled soft plastic. This innovative prototype was created to demonstrate what is technically possible in Australia, driven by the collaborators’ desire to drive a circular future for soft plastics in Australia.

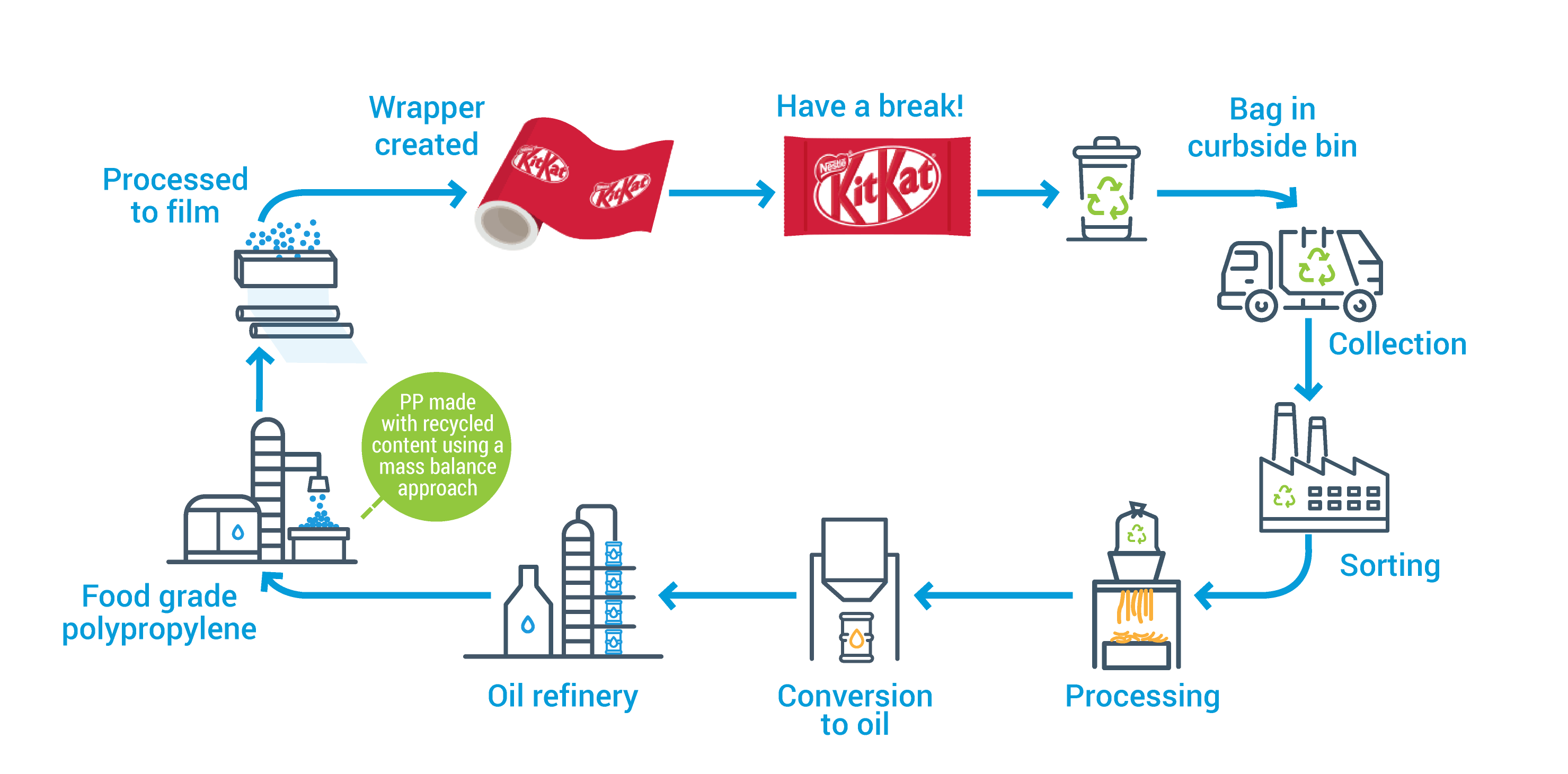

The demonstration project started with a collection trial on the New South Wales Central Coast of Australia, where soft plastic waste was collected from households via a dedicated bag, which householders placed inside their curbside recycling bin. This soft plastic waste was then sorted and processed using advanced recycling, converting it to oil feedstock for use in making the new food-grade soft plastic prototype wrapper. The successful demonstration project was made possible through the collaboration of Nestlé Australia, LyondellBasell, CurbCycle, iQ Renew, Licella, Viva Energy Australia, REDcycle, Taghleef Industries, and Amcor.

LyondellBasell played a key role by providing the expertise to manufacture the polymer materials with recycled content. With the plastic-derived synthetic oil created by Licella and refined by Viva Energy, LyondellBasell produced the recycled content polypropylene, which is used in making the actual KitKat wrapper. Taghleef Industries and Amcor finished the production loop.

With the increase in demand for recycled options and the rise of value chain collaboration, interest in bringing solutions like this food wrapper to market is expected to grow. LyondellBasell is proud to provide innovative recycling technologies, making more circular options readily available for companies.

Learn more:

Closing the Loop in Food Packaging — LyondellBasell Leads, Klean Delivers

As major producers like LyondellBasell pilot food-grade recycled packaging, the demand for clean, circular feedstocks grows. Klean Industries supports this vision by transforming plastic waste into high-quality raw materials through pyrolysis and advanced processing technologies.

Ready to advance your circular packaging goals?

Partner with Klean to source recycled feedstock, deploy plastic-to-polymer infrastructure, or align your ESG initiatives with scalable impact.

Talk to Our Circular Plastics Experts — and bring your sustainable packaging goals to life » GO.

You can return to the main Market News page, or press the Back button on your browser.