Featured Article | EU Biofuel Regulations Could Unlock Bunker Emissions Savings in Maritime Sector

EU Biofuel Regulations Bunker Fuel Emissions Savings

Variations in how jurisdictions classify certain biofuels mean EU bunker buyers could see greater emissions savings than buyers of the same fuel elsewhere.

The recently introduced EU ETS and FuelEU Maritime regulations require ships trading in the EU to pay for their emissions.

Using biofuels helps reduce the cost of compliance, but they are significantly more expensive than conventional fuels. For example, Ship & Bunker data indicates that in Rotterdam, the premium for a B30 biofuel/VLSFO blend over 100% VLSFO is around 50%, or $250/mt.

One such rule variance lies in how the EU’s Renewable Energy Directive III (RED III) rules classify what is considered bio, recovered, and renewable fuel. This can lead to some blend components offering a higher level of emissions savings in the EU than elsewhere.

One such product currently gaining attention is Tyre Pyrolysis Oil, or TPO.

Produced through the thermal decomposition of waste tires, a portion of TPO is considered a biofuel thanks to the natural rubber used in the manufacture of tires.

In many jurisdictions outside the EU, the remaining non-biogenic component of TPO cannot be counted towards emissions savings quotas. But under the EU’s RED III regulations, it can be classified as a Recovered Carbon Fuel (RCF). Such fuels have the potential to be counted towards the offsetting of emissions.

TPO

The extraction process to produce TPO involves heating used tires in an oxygen-free environment, breaking the tires down into three main components:

- Recovered Carbon Black (RCB) that can be used in the manufacture of new tyres, rubber products, and plastics

- Steel wire extracted from tire beads that can be directed for metal recycling

- TPO, a viscous liquid hydrocarbon with an energy content similar to HSFO and VLSFO, meaning it is a good candidate as a blend component for bunker fuels.

The percentage of biogenic content in TPO varies depending on the feedstock being used, but importantly, the biogenic rubber component of the tires is concentrated in the resulting TPO.

As the TPO yield can be as high as 50% of the feedstock tire mass, this means a tire with only 15% natural rubber content could produce a TPO with a biogenic content as high as 30%.

As for the non-biogenic component, to be classified as an RCF under RED III, it must meet specific criteria that include the use of end-of-life tires and the achievement of certain GHG reduction thresholds.

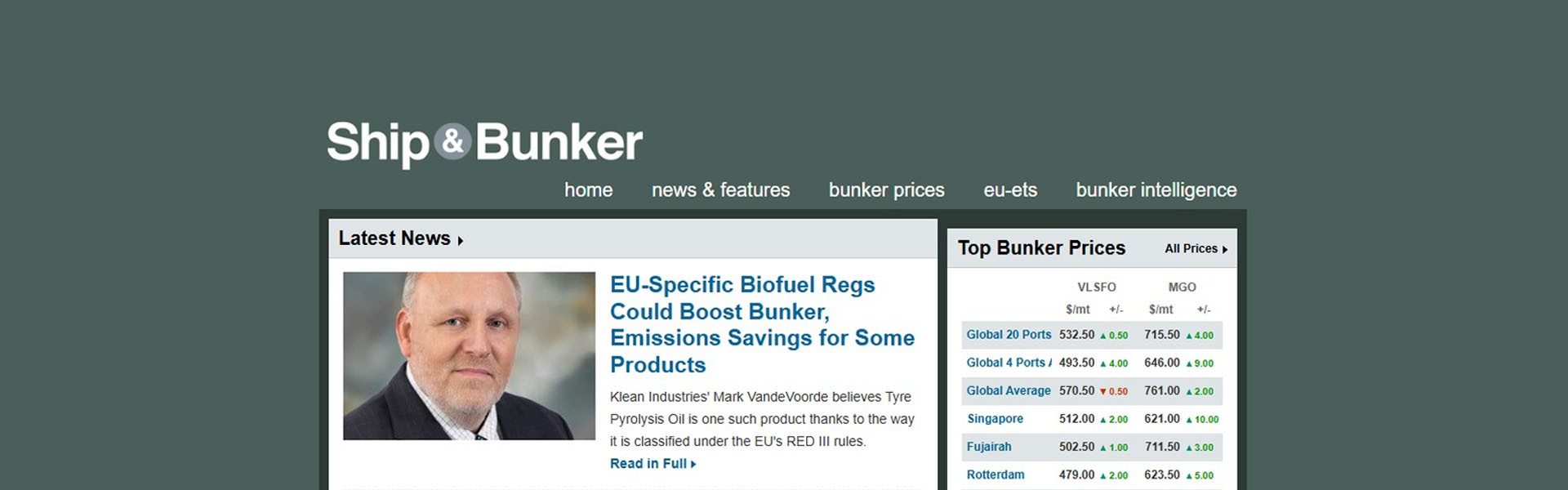

Klean Industries

Canada-based Klean Industries is one company specializing in resource recovery, waste-to-energy, and the specialist thermal processing systems used to produce TPO.

They recently partnered with Viva Energy on the development of a tyre-recycling facility in Melbourne, which aims to process up to 80,000 tonnes of used tyres per year for use in the production of lower carbon fuels.

Mark VandeVoorde, Managing Director of Klean Industries, has some 40 years of experience in the marine fuels industry and believes TPO has high potential as a low-cost blend component for modern bio-bunker fuels.

“Klean Industries Tire Pyrolysis Oil can help to decarbonize the marine fuel industry,” he told Ship & Bunker. “The TPO process envisioned for Melbourne has a 40% biogenic content, with the remaining

60% meeting the criteria to be considered an RCFunder RED III regulations.

The TPO process envisioned for Melbourne has a 40%biogenic content, with the remaining 60% meeting the criteria to be considered an RCF under RED III regulations.

“Further, we’ve confirmed that the biogenic portion of TPO can be considered an AdvancedBiofuel. While individual Member States decide on the implementation of double counting, under EU regulations, Advanced Biofuels can be counted with a 2X multiplier, deepening the potential savings.”

Understanding exactly how much those savings can be is, unfortunately, not easy. This is a relatively new area, with legislation either recently implemented or, in some cases, still under development.

This means that exactly how the savings of the RCF component will be treated by member states and applied to the EU ETS and FuelEU Maritime rules needs to be examined on a case-by-case basis.

But even without those savings, VandeVoorde believes TPO’s credentials as a viable biofuel feedstock remain strong.

“TPO represents a critical solution to reducing carbon emissions from marine fuel at a reasonable cost compared to many other solutions being evaluated by ship owners and operators.

“At current biofuel price levels in the low $700 to mid $800/mt range, TPO projects are very attractive.

“But this is an emerging area, and along with other technologies, it will take foresight and a willingness by industry stakeholders to invest in Tire Pyrolysis projects to access TPO as a low-carbon solution.”

About Martyn Lasek

Martyn is the Founder and Managing Director of Ship & Bunker, the world’s most read marine fuel-focused publication.

With a career spanning over 25 years in building information systems and online publishing, he has been providing critical information to the bunker industry since 2002. Martyn is based in Vancouver, Canada.

About Ship & Bunker

Ship & Bunker is the world’s most-read publication focused on the marine fuel markets. Completely independent, it is the leading industry authority providing comprehensive daily news, exclusive in-depth features and analysis, along with daily and historical bunker price indications.

To contact the editor responsible for this story, email us at editor@shipandbunker.com

Why Klean Industries Is a Strategic Partner for Marine Decarbonization:

As policymakers refine emissions regulations, only those with future-ready fuel solutions will emerge as leaders. At Klean Industries, we support global decarbonization by supplying low-carbon fuels, developing hydrogen infrastructure, and deploying circular resource recovery technologies across hard-to-abate sectors, including maritime shipping.

Whether you’re navigating RED II compliance or investing in carbon intensity reduction, Klean helps partners stay ahead.

Let’s accelerate maritime decarbonization together.

You can return to the main Company News page, or press the Back button on your browser.