SERVICES: KLEAN’S FEASIBILITY EDGE ADVANCING TYRE PYROLYSIS IN ITALY WITH ITALIANA ENERGETICA

Sustainable Development Goals

Project Status:

COMPLETED | Feasibility Study | Project Development 2012 - 2020

Organizations Involved:

Italiana Energetica Tire, Ecopneus, Nippon Steel & Sumitomo Corporation, Nippon Steel & Sumikin Engineering, Steinmüller (Fisia) Babcock Environment Gmbh, Techint Engineering & Construction, Sojitz

Services:

Feasibility Studies, Due Diligence, Component Supply, Packaged Solutions

Introduction

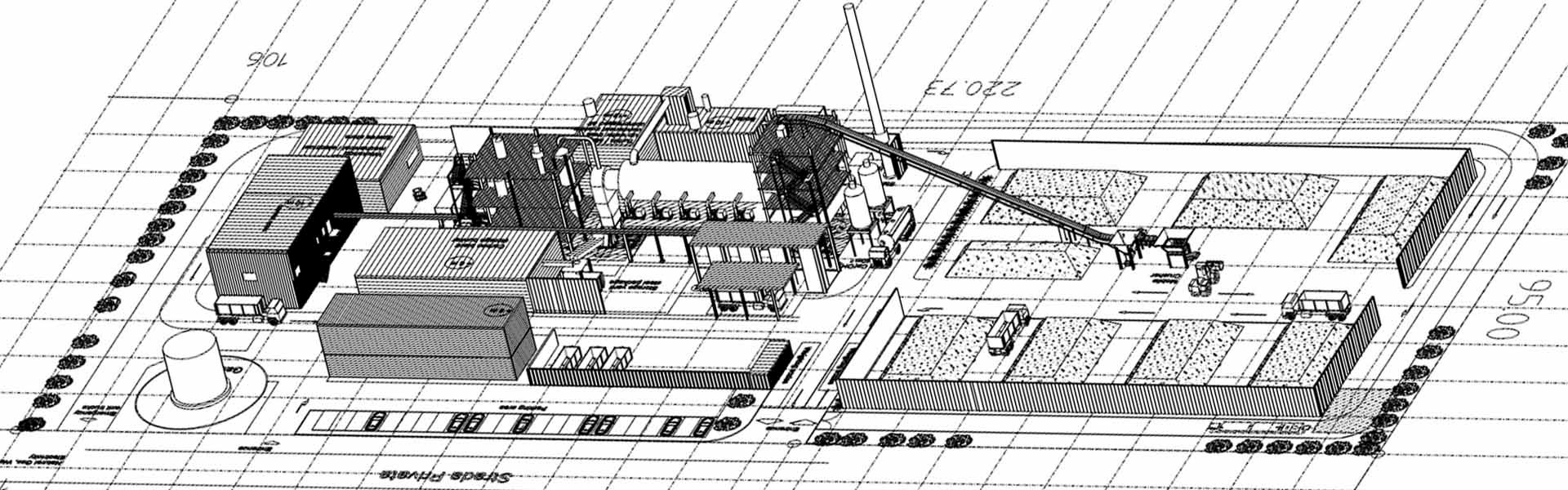

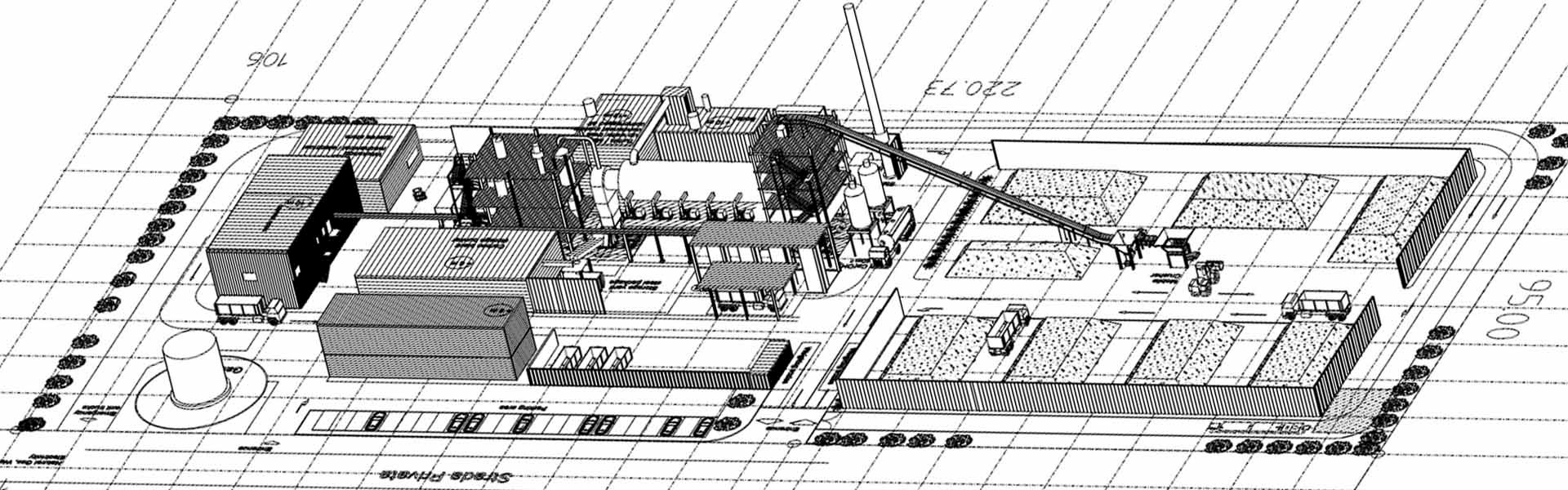

In 2012, Italy required scalable solutions to manage nearly 500,000 tonnes of end-of-life tyres annually, much of which was ending up in landfills or low-efficiency incineration facilities. Italiana Energetica Tyre (IET), led by forward-thinking Italian entrepreneurs and backed by Ecopneus, commissioned Klean to conduct a detailed feasibility study (DFS) for a flagship tyre pyrolysis plant in Milan. Klean’s assignment: assess the project’s viability and roadmap a credible path to success.

The Challenge

- Feedstock Volatility: Despite regulatory frameworks banning landfill disposal (EU Directive 2006, Italian DM 82/2011), domestic infrastructure and EPR systems were immature.

- Unproven Technology at Scale: Proposed pyrolysis plant aimed for 100 tonnes/day (33,000 tpy), but lacked real-world validation.

- Complex Regulatory & Financing Landscape: Navigating feedstock contracts, financing, permitting, and aligning stakeholders created high-risk execution.

- Ambitious Goals, Conditional Reality: The plant was poised to produce low-carbon tyre pyrolysis oil (TPO) and recovered carbon black (rCB)—but required careful validation to reach FID.

Klean’s Strategic Response

- Conducted Detailed Feasibility Study (DFS): Klean investigated technical design, sourcing strategy, financial modeling, and risk mitigation.

- Mapped Regulations & Supply Chain: Klean evaluated feedstock flows under Ecopneus' stewardship and Italian EPR frameworks, ensuring downstream compliance.

- Validated Product Output & Market Demand: Assessed biogenic TPO and ASTM-grade rCB viability for industrial and fuel markets across Europe.

- Advised on Public-Private Collaboration: Aligned technical design with Ecopneus, Nippon Steel, Sumitomo, Techint, and Sojitz, integrating pyrolysis tech into broader supply chain ecosystems.

Project Outcome

- Viability Flagged, Not Ignored: Klean identified key issues to resolve, feedstock stability, plant design, product off-take, enabling IET to proceed toward FID with confidence.

- Klean’S Exit Strategy: After delivering high-impact DFS in May 2013, Klean exited a potential JV/equipment supply role, having clarified the roadmap for success.

- Industry Impact: Klean’s feasibility work ensured capital wasn’t wasted on under-resourced development; it became a benchmark for future tyre-to-fuel projects in Europe.

Learn more:

Leadership Insights

This engagement exemplifies one of Klean’s core strengths: advancing innovative, circular systems through rigor, not guesswork. Rather than building small pilots, we apply full-scope engineering, supply chain scrutiny, and policy alignment to define what’s bankable before a shovel hits the ground.

Klean doesn’t just scope problems; we prescribe and de-risk the solution. Our work with IET demonstrates how experienced feasibility transforms ambition into action, while protecting stakeholders, investors, and the environment.

If you would like to learn more about this project, please get in touch with us now >> GO.

This project addresses the United Nations Sustainable Development Goals (SDGs) by considering the goals and associated targets illustrated by the WBCSD’s Tire Industry Project (TIP). TIP offers a framework for action that outlines impactful pathways for the tire sector to contribute to the ambitions of the SDGs. To learn more about how Klean's approach, solutions, and technologies contribute to advancing the SDGs, please review the report "Sustainability Driven: Accelerating Impact with the Tire Sector SDG Roadmap." See: https://www.wbcsd.org/Sector-Projects/Tire-Industry-Project/End-of-Life-Tires-ELTs